Disclosure: As an Amazon Associate I earn from qualifying purchases. This page may contain affiliate links, which means I may receive a commission if you click a link and purchase something that I have recommended. There is no additional cost to you whatsoever.

Strong, sturdy, low upkeep and extremely immune to each fireplace and water, concrete’s many sensible attributes have made it the world’s hottest building materials. An estimated 30 billion tons are produced globally every year to assemble roads, bridges, buildings, dams and different vital infrastructure.

Nonetheless, concrete’s ubiquity comes with important environmental penalties. An estimated eight percent of all man-made CO2 emissions are brought on by the manufacture of portland cement — a principal constituent of just about all concrete mixes.

Cement Manufacturing: A Major CO2 Culprit

Cement is manufactured by grinding limestone and heating it, together with shale or clay, in a kiln to a temperature of as much as 3,000 levels Fahrenheit. During this course of, CO2 is launched from the fossil fuels used to warmth the kiln, in addition to from gases launched by the limestone itself as calcination takes place throughout heating.

Manufacturing one ton of cement produces approximately 0.8 to 0.9 tons of CO2 emissions. By distinction, substituting that ton of cement with fly ash to supply concrete avoids just about all of these cement-related CO2 emissions — roughly 0.8 tons.

A byproduct of coal-fueled energy crops, fly ash has been utilized in substitution of portland cement for three-quarters of a century within the United States. First specified on a large scale within the 1949 building of Montana’s Hungry Horse Dam as a cost-saving measure, fly ash additionally proved to be extremely efficient at lowering the concrete’s warmth of hydration (serving to to stop thermal cracking throughout curing); bettering the completed concrete’s density, energy and sturdiness; and boosting its resistance to water and chemical compounds. Ready blended concrete producers, then as now, additionally valued fly ash for its skill to enhance the workability and pumpability of contemporary concrete.

high quality than current-generation ash throughout a variety of

efficiency standards.

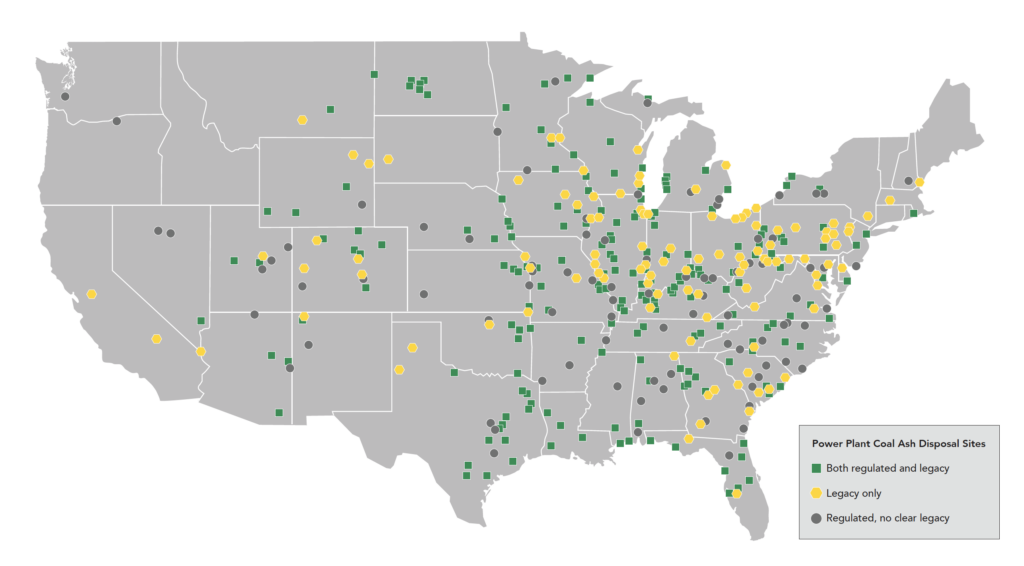

In the 75 years since, concrete producers have beneficially used tons of of tens of millions of tons of fly ash to seize these identical value financial savings and efficiency enhancements. The unused fly ash produced by coal crops over this era — estimated at roughly two billion tons — has been saved in landfills and floor impoundments.

A Vast, Untapped Resource

As the retirement of coal crops continues apace at the moment within the United States, and the provision of contemporary fly ash decreases, these landfills and impoundments stand as an unlimited useful resource that concrete producers can make the most of as fly ash provide for many years into the long run. Recognizing this, the U.S. supplies business has labored to develop consensus requirements to encourage accountable “harvesting” of beforehand disposed ash. After years of session amongst business stakeholders, ASTM C618, Standard Specification for Coal Ash and Raw or Calcined Natural Pozzolan for Use in Concrete, now acknowledges that fly ash might come from a harvesting web site slightly than immediately from the ability plant, topic to processing to make sure its concrete-grade high quality.

Already there are greater than a dozen harvesting websites deliberate or in operation within the United States, which, in accordance with the American Coal Ash Association, added over 4 million tons of concrete-grade fly ash to the market in 2022, the final 12 months for which knowledge can be found. That quantity is the same as 8.7 p.c of the whole ash recycled from present energy plant operations.

produce 2 million tons of fly ash over the mission’s life.

Beyond its worth in decarbonizing concrete, the provision of harvested ash — notably as this observe turns into extra widespread — will inevitably imply that ash entrepreneurs and their prospects are much less constrained by provide uncertainty associated as to whether or not coal-fueled energy crops are working and producing contemporary ash. Reliability of provide, mixed with the standard of product that the beneficiation of harvested ash ensures, are each vital to making sure that mission builders specify fly ash to be used in concrete.

Eco Material Harvesting Projects

For these causes, my firm, Eco Material Technologies has made identifying and developing suitable harvesting sites all through the U.S. a central a part of its marketing strategy and has numerous main initiatives within the pipeline, together with the next:

- Harvesting and beneficiation of greater than 100,000 tons of fly ash yearly has been underway since 2019 at an Eco web site in Pennsylvania, which has the capability to supply 2 million tons of fly ash over the mission’s life. More than 1.5 million tons of CO2-equivalent emissions are in the end anticipated to be prevented by means of the usage of this materials in concrete manufacturing. Among different initiatives, harvested ash from the Montour landfill has been used to construct and refurbish concrete components of the Lake Williams Dam, close to York, Pennsylvania.

- Operations now underway at two harvesting websites within the Southeast are anticipated to supply roughly 1.2 million tons of ash yearly from landfills and floor impoundments as soon as they’re totally operational. Over the lifetime of those initiatives, roughly 17 million tons of ash will probably be harvested to be used in building initiatives all through the area that may stop as much as 15 million tons of CO2-equivalent emissions from getting into the ambiance.

- With current revisions to the ASTM C618 customary specifying that backside ash is appropriate to be used in concrete, topic to sure situations, Eco Material is commencing backside ash harvesting and grinding at a web site in Texas to extend out there concrete-grade blended ash provides within the area. The plant has been sized with future upside capability that may enable it to supply as much as 700,000 tons per 12 months if wanted.

- Eco Material has entered right into a partnership to beneficiate and market as much as 150,000 tons of harvested ash yearly from a Gulf Coast web site. The deposit has practically 3.5 million tons of fly ash out there, making this a long-term partnership between the events.

- At a separate Gulf Coast web site, Eco has reached an settlement to beneficiate and market beforehand disposed fly ash that may generate roughly a further 600,000 tons of sustainable materials per 12 months when it’s totally up and operating. Operations are anticipated to start in early 2026.

- Eco Material is partnering to construct new backside ash and gypsum beneficiation and harvesting crops within the Upper Midwest that may present a further 400,000 tons yearly of supplementary cementitious materials over the following 25 years to service quickly rising markets within the area.

There is not any “silver bullet” to decarbonizing the concrete sector; business should spend money on a variety of supplies and applied sciences to have the ability to obtain net-zero emissions. Given the urgency of the problem, nonetheless, ash harvesting provides a confirmed answer that may make impactful reductions to concrete’s carbon depth now — slightly than within the distant future.

About the Author

Grant Quasha is Chairman and Chief Executive Officer of Eco Material Technologies, the main producer and provider of sustainable cement options in North America. Eco’s proprietary Green Cement expertise makes use of fly ash and different pozzolanic supplies to supply modern, near-zero-carbon merchandise as sustainable substitutes for portland cement in concrete. Listen to Grant’s conversation on Sustainability in Your Ear for extra on the highway to low-carbon infrastructure.