Disclosure: As an Amazon Associate I earn from qualifying purchases. This page may contain affiliate links, which means I may receive a commission if you click a link and purchase something that I have recommended. There is no additional cost to you whatsoever.

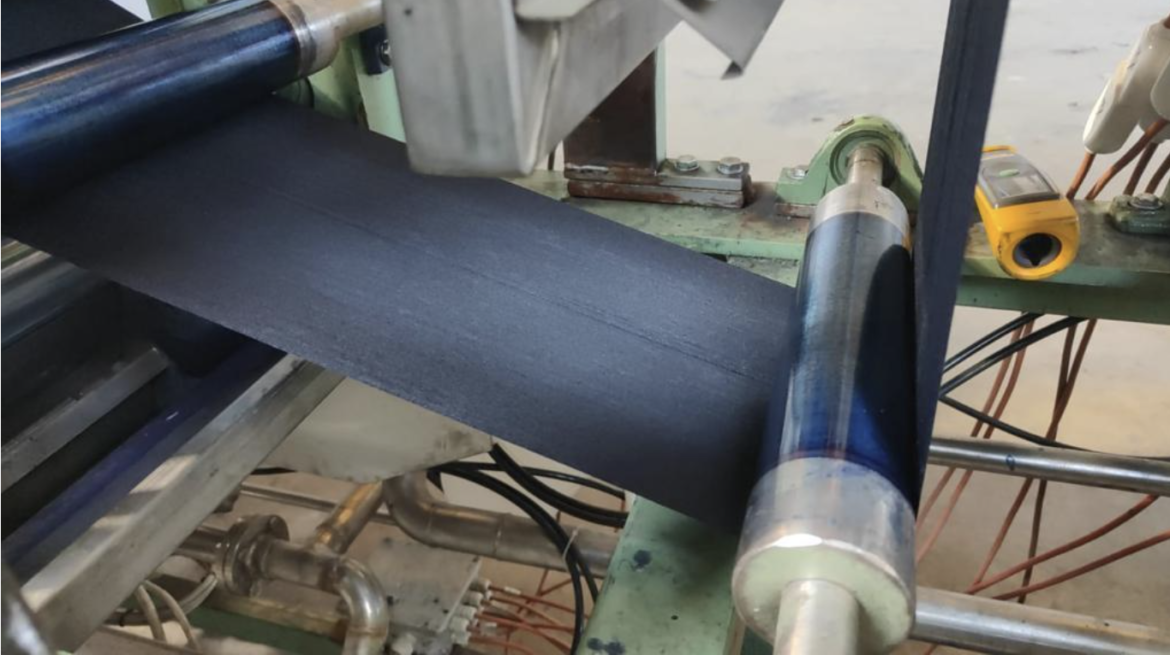

A Sonovia machine dying material in a extra sustainable method. Via the usage of physics, Sonovia is harnessing the facility of ultrasonic cavitation jet-streams to impregnate textiles with colour.

Sonovia is taking the textile business into the long run as we communicate, creating the most recent method of manufacturing in vogue. I spoke with Shay Hershcovich, the co-founder of Sonovia: “It takes eleven-thousand liters of water to provide one pair of denims,” Shay says. Another downside: the large quantities of wastewater dumped because of unsustainable textile manufacturing has turned the Jian River in China purple from dye.

Shay and the remainder of his staff at Sonovia are working lengthy and arduous to revolutionize the textile business. By breaking away from outdated strategies of dyeing and ending manufacturing practices, Sonovia goals to create a sustainable future for textile manufacturing. According to Sonovia, they declare to “depart probably the most important mark on the textile business since its inception and to allow humanity to benefit from the textiles that encompass our lives with a clearer conscience.”

The Jian River in China contaminated with purple dye through ecohubmap.com

Developed initially at Bar Ilan University exterior of Tel Aviv, Sonovia is increasing the brand new expertise of utilizing ultrasound soundwaves to chop down emissions within the textile business. Via the usage of physics, Sonovia is harnessing the facility of ultrasonic cavitation jet-streams to impregnate textiles with colour. Like “chemistry weapons”, they name it, the expertise works to generate cavitation bubbles that implode and generate 1,000 meter/sec jet-streams.

Sonovia’s ultrasonic dyeing machine

Related: She puts consciousness in her textiles using natural indigo

The machine is known as Sonofix, manufactured and provided by their companions at Bruckner Trockentechnik GmbH. Sonovia affirms this equipment to have breakthrough sturdiness and efficiency, non-toxic chemistry, and 100% agnostic to fiber sort, in addition to being price aggressive.

Leading European textile equipment maker Bruckner companions with Sonovia to chop carbon footprint of clothes manufacturing forward of latest European guidelines. From left, Sonovia CEO Igal Zeitun, Sonovia proprietor Shuki Herschkovitz, Brückner Textile Technologies proprietor Axel Pieper. Photo courtesy of Sonovia

In addition, Sonovia has different companions everywhere in the world, together with firms throughout Asia, and in Germany and Italy. The French Luxury group, Kering, which owns massive manufacturers comparable to Gucci and Saint Laurent even determined to combine Sonovia’s expertise into their manufacturing strategies for the withseen future.

Sonovia can dye denims with 90% much less waste

Pictures of Sonovia’s expertise

According to a research produced by Made2flow, an organization that focuses on testing the environmental impacts the textile business has, Sonovia’s expertise reduces greenhouse fuel emissions by 60%, 85% in water use, 99% in polluting wastewater, and 90% in land utilization, in comparison with the standard industrial dyeing means of denims.

Their expertise has been examined in labs around the globe, together with Hohenstein, VisMederi Textyle, Microbe Investigations Switzerland (MIS), and Bureau Veritas.

Sonovia’s merchandise embrace an revolutionary and sustainable technique of indigo dyeing and odor-controlling expertise. The present challenge D(y)enim, is the indigo dyeing system that makes use of indigo pigment dispersion to save lots of water and be extra eco-friendly.

Related: the secrets of Israel’s holy blue

Unlike the standard technique, D(y)enim solely contains 2 dye baths, no redox/oxidation dyeing mechanism, and leads to no hydrosulfite waste. There is not any want for merceization/scouring prep course of earlier than dyeing or want for a number of wash baths after the dyeing baths passage. In their current research, the manufacturing of 1 pair of denims utilizing their expertise saved 9.8% of water, equal to 160 days of consuming water per individual on common.

In addition, the research concluded that 4% of GHG was saved, equal to 12 Km pushed by a mean non-public automotive. And lastly, it saved 1.4% of land use, equal to 249 grams of flour produced from equal land use.

Sonovia has created a course of for utilizing much less dye and water for sustainable vogue. These are denims dyed with the Sonovia course of

As Sonovia continues to develop internationally, its mission is to function the face of sustainable textile manufacturing shouldn’t be bleak. The Future of Sonovia seems propitious, particularly because the local weather disaster continues to demand change in our society. With the immense analysis proving Sonovia’s expertise massively saves monumental quantities of water, CO2, and land-use, in addition to being less expensive, firms around the globe proceed to be impressed to undertake Sonovia’s expertise. The firm has even been listed within the Tel Aviv inventory trade (TASE: SONO).

Ittai Ben Zeev, Joshua Herchcovich, Aaron Garzon, Yaron Yaacobi, Liat Goldhammer, Shay Hershcovich, and Yana Chernyak at TASE’s Listings Unit

To be taught extra about Sonovia, take a look at their website.

#wpdevar_comment_1 span,#wpdevar_comment_1 iframe{width:100% !necessary;} #wpdevar_comment_1 iframe{max-height: 100% !necessary;}

Comments

feedback